History

Birth of Kiviõli Keemiatööstus

1920-1930

In 1920, the Estonian mining agency issued a permit to the German capital-based paper and cardboard company PLC Põhja for “scouting” the area between Sonda and Püssi train stations. In 1922, the factory transferred all the rights and obligations to the public limited company Eesti Kiviõli that established an oil shale quarry on the Erra-Sala village grounds, where open-cast oil shale mining began. This boosted the development of the surrounding area and made the establishments nearby grow rapidly. In 1924, the company started practical works with thermal oil shale processing. In 1927, the first trial tunnel oven with a capacity of 75 tonnes of oil shale per 24 h was constructed. In 1928, the settlement that had started to swiftly expand near the industry was called Kiviõli. In 1929, the company was operating two industrial tunnel ovens with a total power of 500 t/24 h.

1930-1940

In 1930, the company transferred to underground mining. A year later, the Franz Krull factory finished the first oil and petrol plant with two tunnel ovens, which became the predecessor for the Kiviõli oil shale chemical plant. The plant produced 86 tonnes of fuel oil and 12 tonnes of petrol a day. A train station was built in the vicinity. In 1936, the union was established and the same year also saw the first miners’ strike. In efforts to stop the strike, Polish coal miners were used as cheap labour. In 1938, the Kiviõli mine became the largest in Estonia, producing more than 0.5 million tonnes per year. In 1939, a two-week paid holiday was enforced for the workers which had not been provided before. The oil shale industry was growing rapidly in the region and by 1940, shale oil provided 8% of the total export income of the entire country.

1940-1960

In 1941, the mine and plant equipment was taken to Russia. On 10 August 1941, the German army invaded the plant and in July, the papers transferring the entire oil shale basin to a company called Baltische Ölgesellschaft in Estland were prepared. Over the following three years, the Germans built grand industrial facilities with two brand new tunnel ovens, eight gas generators and a power plant. During this time, workers of various nationalities were brought in as well as prisoners of war who worked in separate divisions. During the German occupation, a new circular shaft yard was built at the Kiviõli mine which lasted without repairs until the mine was closed thanks to the monolith reinforced concrete used in its construction. When the German army left, the mine and the plant were demolished and the Kiviõli and Küttejõu mines were drowned.

On 24.09.1944, the Soviet army started restoring the mine and the plant. A year later, the two new tunnel ovens started working and the new petrol plant finished its first product batch. In 1947, another tunnel oven was launched as well as the thermal power station. From 1948 to 1954, underground thermal oil shale processing was tested in the northern section of the Kiviõli mine; the testing continued until 1960. In 1950, the transfer to gas power began for the tunnel ovens, around the same time, sleeper treatment oil was also present in the product selection. In 1951, the Kiviõli and Küttejõu mines were joined. In 1952, the construction works for the new administrative and domestic building for the mine started. The building was finished in 1955. By 1953, six new generators were in operation and the new solid heat carrier testing device with a capacity of 200 tonnes of fine oil shale in 24 h was finished. The same year, coating lacquer called kukersool was added to the product selection.

1960-1980

In 1963, the new oil shale sorting room was launched with two more generators and a TSK-500 machine, which was employed until 1981. Detergent and formalin plants were opened throughout the 1960-70s. On 12.11.1965, the Kiviõli mine was transferred to the coal mining ministry of the Soviet Union, meaning the Kiviõli mine became a separate company. In 1970, the plant experimented with producing nerosiin and the first industrial batch of oil shale product sulfinool was obtained. At the same time, a system was implemented which allowed the management of the technological process of the tunnel ovens via one central control panel and the central chemistry laboratory developed a quality management system. In 1975, the stove plant was closed and along with it the mine’s double faces.

1980-2000

In the 1980s, the list of products manufactured based on the shale oils and water-soluble shale oil sulfinools produced in the plant included more than 30 articles, including mastics, lacquers, epoxies and other resins. Water-soluble phenols were shipped to Russia as raw material for tanning agents. Due to the price of petroleum products falling below 10 dollars a barrel, Kiviter AS went bankrupt in 1998 and the plant was closed for 10 months. In 1999, T. R. Tamme Auto OÜ purchased the vacant and ransacked plant. There was a need for oil shale raw material once again.

2000-current day

In 2003, the North Kiviõli oil shale quarry obtained a mining permit and selective oil shale mining began. In 2004, a mining permit was obtained for the Moldova mine. In 2006, a mining permit was obtained for the Kolustre gravel quarry and at the end of the same year, the 30-million kroon Wirtgen 2500 surface miner arrived at the oil shale quarry. In 2011, a mining permit was obtained for the North Kiviõli II oil shale quarry where selective oil shale extraction is still going on today. In 2012, Alexela Group acquired 50% of the company and another Wirtgen 2500 surface miner arrived at the oil shale quarry. In 2013, in collaboration with Reola Gaas, LPG fuel was taken into use in trucks. In 2014, Alexela Group acquired the company and established a new tank park. In 2015, a full-power solid heat carrier machine started working. The following year, both solid heat carrier machines were operating and the sale of phenols was relaunched. In 2017, a 1.8-million-euro contract was signed for installing an electrical filter for the solid heat carrier machine; the work was completed in 2018. The company continues to make major investments to reduce environmental impact and increase production volumes.

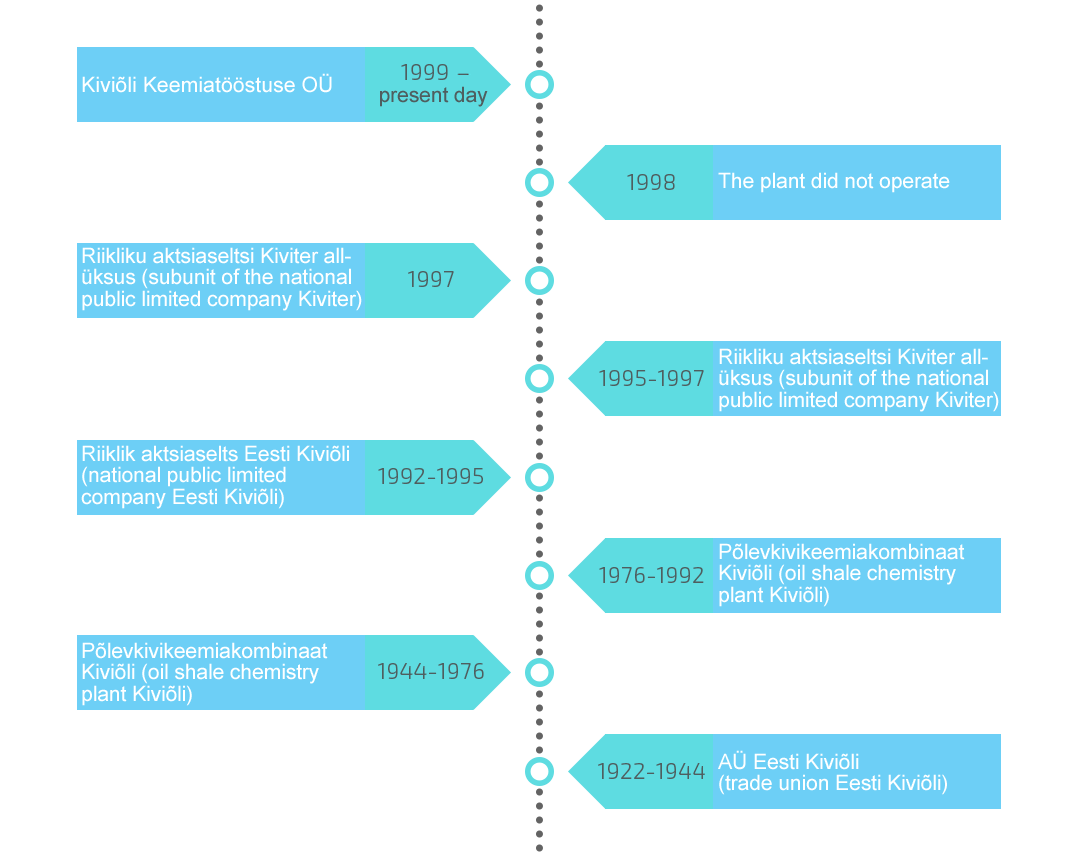

Company name throughout the years

Kiviõli Keemiatööstus (Kiviõli Chemistry Industry) has borne various names over time, but the substance has remained the same – shale oil is the main product.